One of my favorite things about my time here so far is the ability to get familiar with infrastructure I wouldn’t be able to see back home. I was recently able to take a tour of the McMurdo Wastewater Treatment Plant (WWTP), Building 199.

The McMurdo Wastewater Treatment Plant is right at the waters’ edge. Water flows downhill! There’s only a few buildings that require a lift station to get their wastewater to the plant.

Most infrastructure in McMurdo is above ground. It’s easier to maintain this way, and it doesn’t require (challenging and fraught) below-ground excavation. Most everything has heat trace wiring and thick insulation, to ensure the contents don’t freeze.

Wastewater all flows down to the wastewater plant.

Fun fact 1: The wastewater plant needs a comparatively small staff to operate, which means this building has the most square footage per employee. It’s peaceful in here! Mostly the gentle hum of machinery.

Fun fact 2: Humidity! This building is heated and has a huge amount of indoor open water. Pretty much nowhere else on station has this. It feels and smells pleasant, like a slightly humid, earthy summer day. Since I’m totally deprived of these sensations anywhere else on station, it’s really lovely in here. Even at my job, I’ve jumped to volunteer for any tasks that allow me to spend time in this building.

I’ll preface this by stating that I’ve come here for a single tour, and I do not work here professionally! I’m purposefully being vague on the details, because this isn’t my area of expertise and I don’t want to misstate something about how the plant operates.

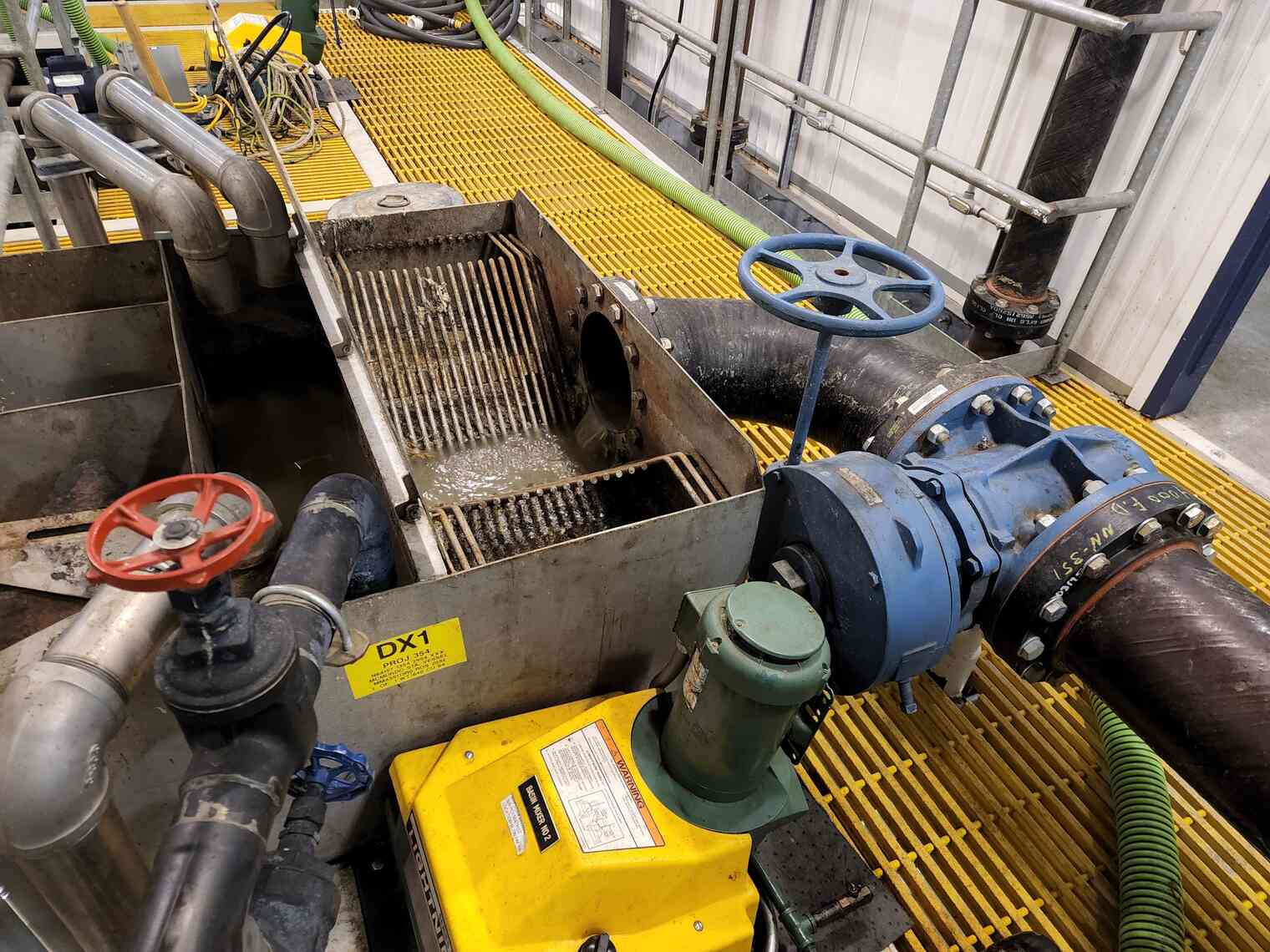

Raw wastewater enters the plant and flows through macerators. These break up solids into manageable pieces.

Here we can see the raw (macerated) wastewater flowing in. No… visible chunks in this one, but this is where you’d see ‘em.

The wastewater flows through a strainer, which catches solids that don’t belong in the system.

Here’s the main area of the plant, showing the broad layout of equipment. You can see the aeration basins, where air bubbles are used to mix the incoming wastewater with activated Sludge. The Sludge helps break down and process food and solid waste particles in the wastewater.

The water and Sludge mixture moves onto a clarifier, which uses gravity to separate the two parts.

Some Sludge is recycled back into the system for processing more wastewater, and some Sludge moves on.

The Sludge that isn’t recycled gets sent to a digester, where it is further processed over a period of weeks. Then it is sent to a compressor system:

This squeezes out most of the remaining water, so the resulting Sludge is as light as possible.

Here’s the final solid product, a nutrient-rich soil-like material. This is sent back to the United States.

The water itself moves onto a final UV disinfecting stage:

At last, the treated wastewater is discharged into McMurdo Sound.

Here’s the outflow pipe leaving the plant:

And heading out into McMurdo Sound:

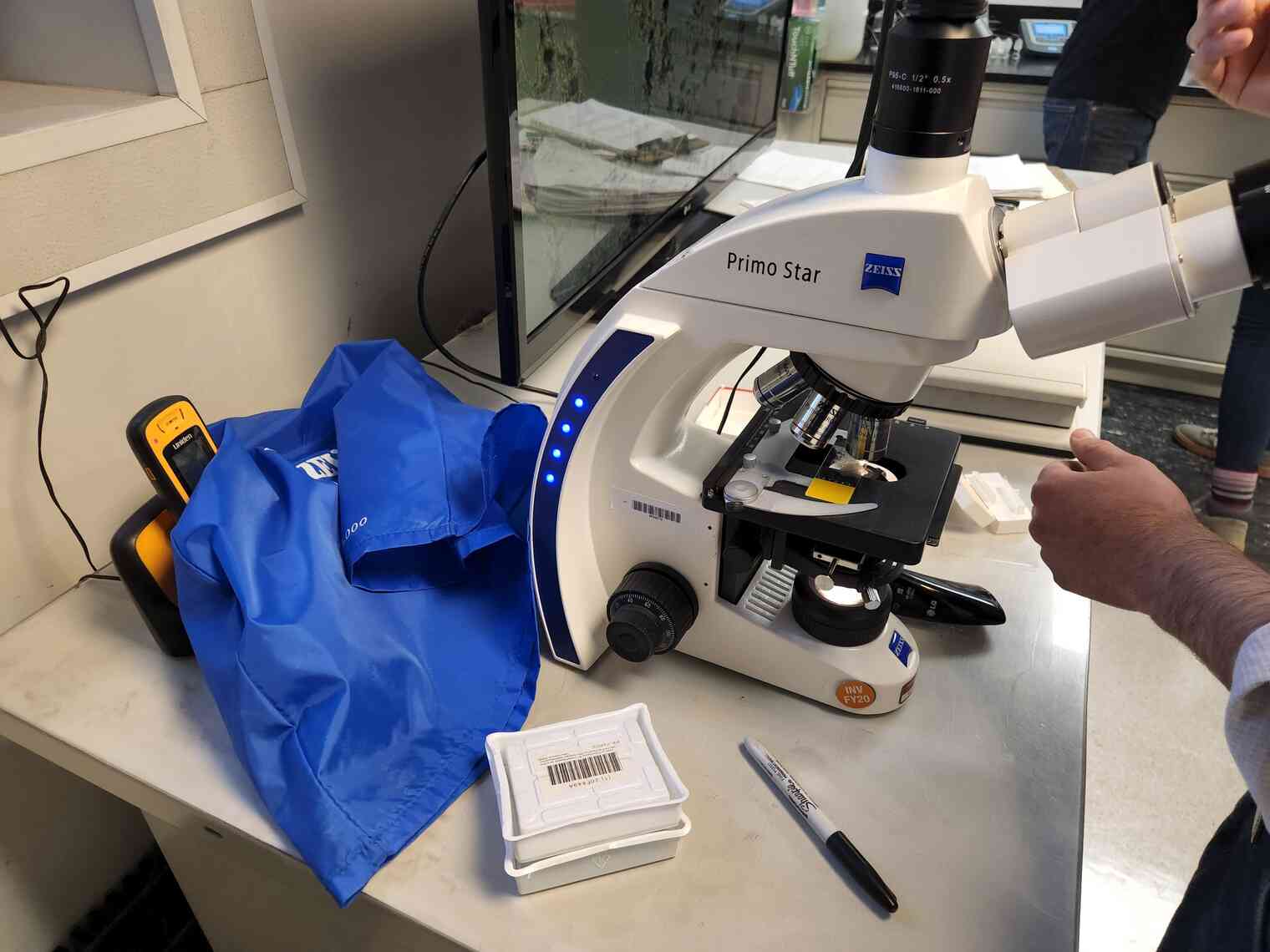

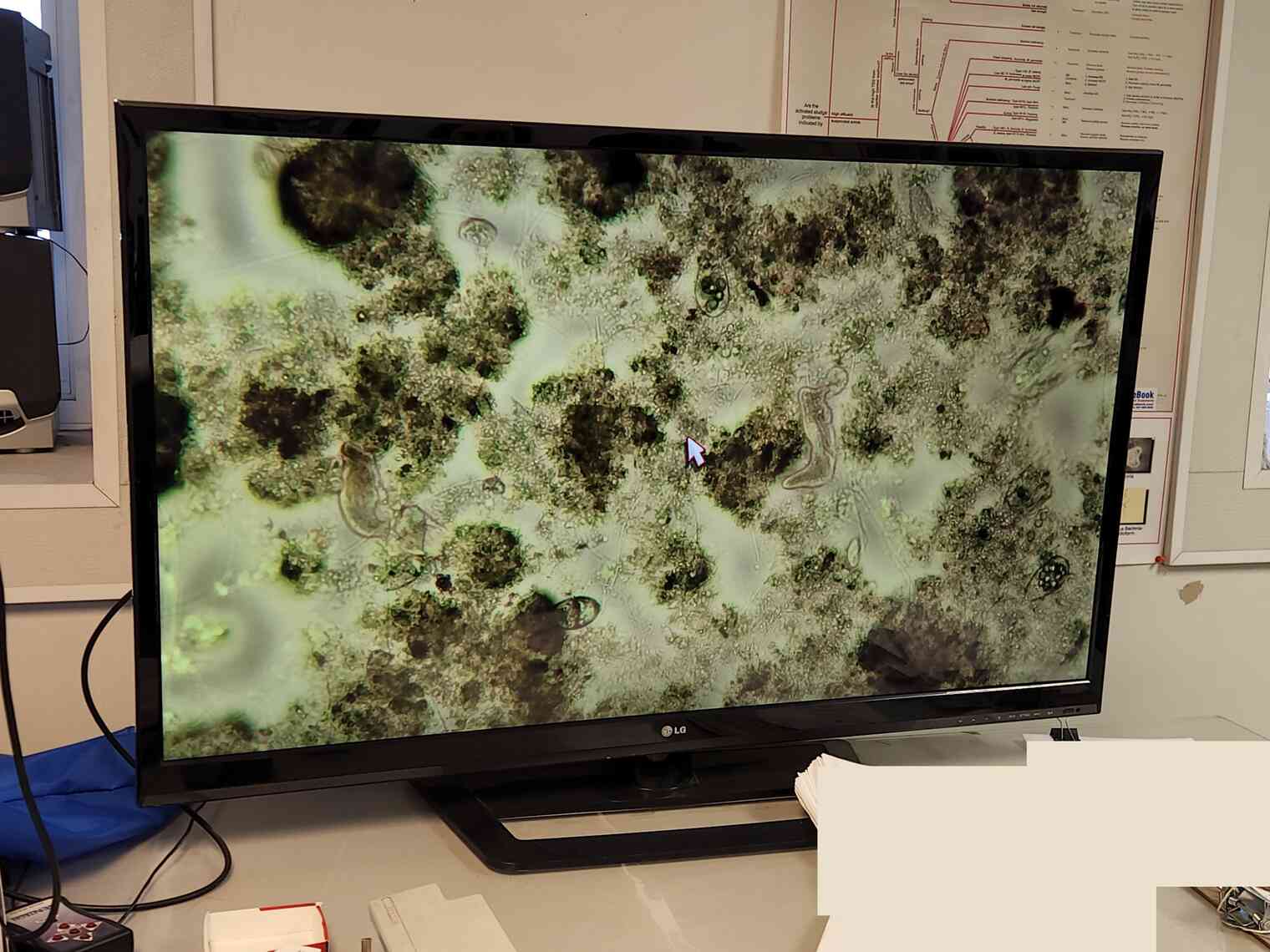

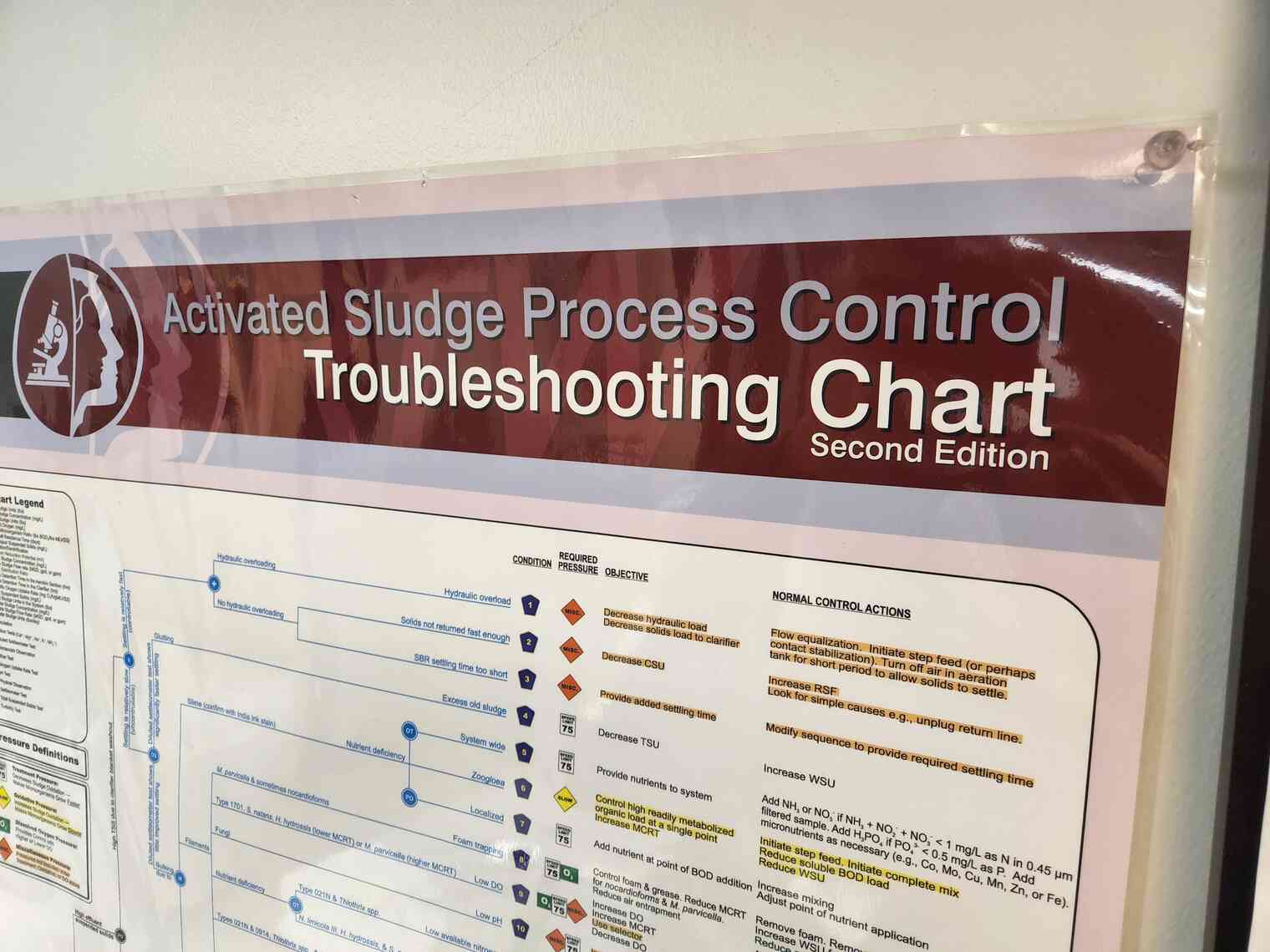

Maintaining the Sludge is a complex process. The plant has a lab, where the Sludge is sampled, tested, and adjusted to maintain optimal health:

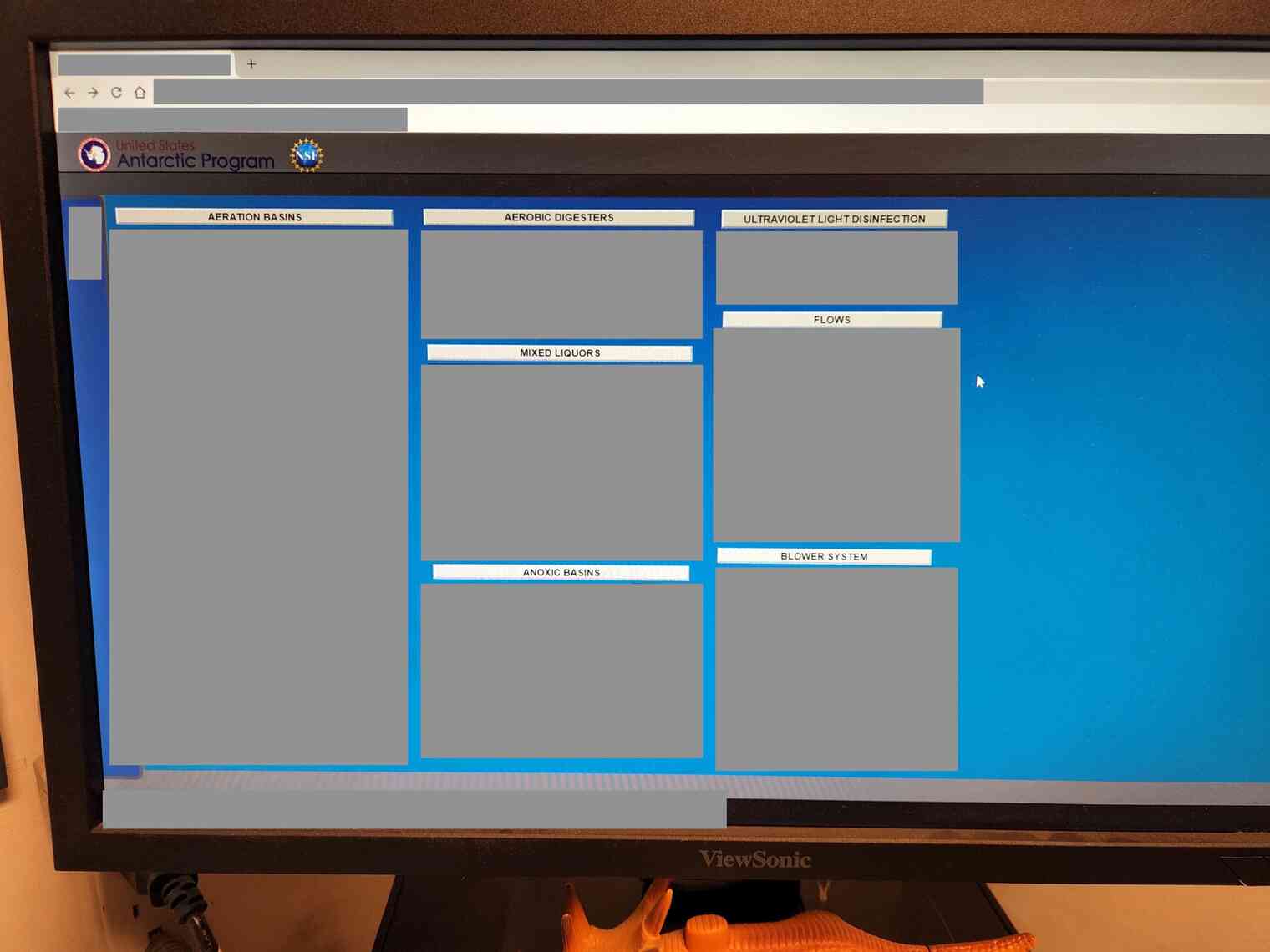

Finally, as with any complex plant, there are elements of information technology and digital controls used as part of the management process. Sorry folks, this one has to be redacted quite a bit, but you get the idea.

I love this kind of stuff, and I’ll jump at any opportunity to see more of it.

Until next time!